There are 3 types of sugar:

- Monosaccharides

- Disaccharides

- polyols (sugar replacers)

There are 3 types of Monosaccharides (simple sugars):

- Glucose (found in fruits and vegetables and is the form of sugar absorbed by the human blood

- stream)

- Fructose (found in fruits and vegetables)

- Galactose (found in cow’s milk)

There are 3 types of Disaccharides (combination of 2 Monosaccharides):

- Sucrose (Glucose + Fructose), known as refined table sugar but also occurs naturally in plants

- Lactose (Glucose + Galactose), known as milk sugar

- Maltose (Glucose + Glucose), know as malt sugar

Sugar Cultivation

- Sugarcane

- Sugarbeets

Sugarcane

A sugarcane plant puts out another stalk immediately after the most recent mature stalk has been harvested (usually cut by hand). Thus, a planted field can be harvested several times however each successive stalk has a lower sugar yield than the previous stalk. When the harvest is no longer viable the field is usually burnt off and then a new field is planted from cuttings (not seeds).

Cuba, India, Australia, Thailand, China and Brazil are among the leading sugarcane producers. Cuba, the EU (sugarbeets), Australia, Thailand, Brazil, Ukraine (sugarbeets) and China are the largest exporters. Overall, Brazil is the largest producer of sugar. The bulk of sugar consumption is concentrated in the industrialized nations. The Russian Federation, EU, U.S., China and Japan are among the world's largest sugar importers. As of 2006, more than 50% of sugarcane crop production in Brazil is now being devoted to ethanol production (most of it consumed locally in Brazil).

Cuba was once the largest exporter of sugar (from sugarcane) in the world and still has extensive sugarcane cultivation although its output has been declining steadily for years. However, in April 2006, the Government of Cuba indicated that it is soliciting direct foreign investment in sugar milling and cultivation operations on the island. It has been suggested that with the increase in the price of sugar related to Ethanol demad, the nation is trying to restart its antiquated operations. There is the issue of the Helms-Burton law in the United States, which mandates penalties against foreign investment in government expropriated Cuban properties and operations and how this statute may affect foreign companies seeking to do business in Cuba.

Beet Sugar

Beet sugar comes from the sugarbeet plant, is grown in temperate climates and accounts for the balance of world sugar production (after sugar cane), and stores sugar in the white root (approximately 16% sugar). A biennial, sugarbeets are harvested annually for their roots. The source of one third of the world’s sugar, sugarbeets are considered to be one of the newest commercial crops. Starting in the late 18th century, German scientists began to breed beets to increase the sugar content of their roots from 1-4 percent to 15- 20 percent. The resulting beet root is narrow in shape with a white root. Sugarbeets are grown commercially throughout the world in cooler, temperate climates. The main producers around the world are France, Germany, Poland, Russia, Ukraine, and the United States (the Russian Federation, Ukraine and Europe produce about 80% of all sugar beets).

The seedlings are referred to as cotyledons ans are susceptible to Soil diseases, insects and crusted soil when first germinated and as young plants. Once the plants become established they are able to withstand wet weather conditions and insects but do require weed control and wind erosion protection and must also have fertilizer applied (however excess nitrogen can have an adverse effect on both sugar content and clear juice purity). At harvest, the plant's leaves are first stripped by a mechanical defoliator and then the remaining beet root is mechanically extracted from the soil.

Commonly confused with red beets, sugarbeets have a white root and are not edible when harvested. Rather, the beets are hauled to the local mill where they are washed, sliced into long, small pieces known as cossettes and processed through hot water tanks known as a diffusor. The sugar is suspended in the water, which is then processed through a series of filters to remove the sugar.

When sugarbeets are processed into sugar, the entire beet is used. After sugar and molasses are extracted from the beet, the remaining pulp is processed into a nutritious cattle feed. Beet pulp is the fibrous vegetable matter of the sugar beet which remains after sugar has been extracted. Following the diffusion process, pulp presses and gas-fired dryers remove water from the pulp. It is then formed into less bulky pellets which saves on freight costs and produces less waste. One ton of sugar beets produces 110 pounds of pulp pellets. Beet pulp pellets are very useful as a highly nutritious, palatable, and absorptive feed for cattle. It is a high-energy easy-to-digest food that helps to stimulate milk production.

Sugar Refining

After being harvested, the sugar cane is sent to the refinery (sugar is always transported in a raw or partially refined condition as humidity will damage a fully refined bulk shipment) where it is first washed to to remove soil and impurities.

During the refining process, the natural sugar that is stored in the cane stalk is separated from the rest of the plant material by

a) grinding (cutting / chopping by high speed revolving blades, mashing / crushing in rollers and adding water to flush the cane juice) the cane (within 24 hours of harvest in order to avoid naturally occurring wild yeasts from settling into the cane) to extract the juice from the fibrous material;

b) boiling the juice (which is already approximately 17% sugar) until the syrup thickens and crystallizes (in older days the fuel for the boilers was the cane stalk fibers, also known as bagasse, left over from the crusher).

The raw cane juice is usually first transferred to a holding tank where it sits for a few hours to allow solid impurities to sink to the bottom of the tank and other non-sugar solids are flocculated by alkalization (this process is known as clarification).

- The juice of the cane plant is then processed to extract the sugar (sucrose / white table sugar) by heating it to the point of evaporation.

- What is left after this process is a syrup and crystalized sugar particles.

- After the sugar is crystallized in vacuum pans, the crystal/syrup is discharged into cooling crystallizers and retained for approximately 32 hours to optimize the crystallization.

- The product is then separated in the low raw centrifugals, with the crystalized sugar being extracted from the liquor (clarified concentrated cane juice).

- The residual syrup left after this process (first boil) is known as molasses (melaza in Spanish). Although molasses is approximately 50% to 54% sugar, the concentration of non-sugars is so high that no further crystallization is economically possible in a standard processing facility. The molasses is stored in large tanks to be shipped to Distillers (additional boiling could be done to create Second Molasses, and then blackstrap molasses is created from a third boiling, which is utilized in the manufacture of cattle feed).

Beet sugar processing is normally accomplished in one continuous process without the raw sugar stage. The sugar beets are washed, sliced and soaked in hot water to remove the sugar-containing juice. The juice is purified, filtered, concentrated and dried in a series of steps similar to sugar cane processing.

Raw sugar is a tan to brown, coarse granulated solid obtained on evaporation of clarified sugar cane juice. Raw sugar is processed from the cane at a sugar mill and then shipped to a refinery. It is about 98% sucrose. Raw sugar is not sold to consumers. The U.S. Food and Drug Administration notes raw sugar is “unfit for direct use as food or as a food ingredient because of the impurities it ordinarily contains.”

Turbinado sugar is raw sugar that has been refined to a light tan color by washing in a centrifuge under sanitary conditions. Surface molasses is removed in the washing process. In total sugar content turbinado is closer to refined sugar than to raw sugar. It can be purchased in many health food stores and some supermarkets.

Brown sugar consists of sugar crystals contained in a molasses syrup with natural flavor and color components. Many sugar refiners produce brown sugar by preparing and boiling a special syrup containing these components until brown sugar crystals form. In the final processing the crystals are spun dry in a centrifuge; some of the syrup remains giving the sugar its characteristic brown color. Other refiners produce brown sugar by blending a special molasses syrup with white sugar crystals.

In Spanish, sugarcane is caña, sugar is azúcar, and the types are refino (refined), blanco (white), moreno

(slightly processed / poco proceso) and crudo.

Sugar Producing Nations

The supply-side outlook for sugar in 2009 is being influenced by recent production shortfall in India, a contraction of production in the European Union and an increase in production in Brazil.

AustraliaThe country is one of the world’s largest exporters of raw sugar. In Australia sugarcane is cultivated in the in high-rainfall coastal areas and river valleys of Queensland (Ord River area; Mary River area; Mossman in Far North Queensland to Beenleigh south of Brisbane and, more recently, on the Atherton Tableland, west of Cairns), coastal areas of New South Wales and Western Australia. In Australia, The sugarcane harvest season generally extends from June until mid-November. Bundaberg Sugar is the largest sugarcane grower in Queensland, along with Maryborough Sugar Factory Limited (also manufactures raw sugar).

The Australian Sugar Milling Council (ASMC) indicates that the "Queensland sugar industry produces about 35 million tonnes of sugarcane from 400,000 hectares annually. This sugarcane crop produces approximately 5,000,000 tonnes of raw sugar, 1 million tonnes of molasses and 10 million tonnes of bagasse annually" (bagasse is burned for electricity and steam generation).

Queensland Sugar Limited (QSL) is a sugar marketer, which works with 8 mills in Queensland, and manages a pooling arrangement for export sugar in Australia, operate six bulk sugar terminals in northern Australia, and handles more than 90% of the nation’s sugar exports, especially to the Asian sugar market.

Australia has had some problems with the introduction of sugarcane smut disease, which led to the introduction of new smut-intermediate and resistant sugarcane varieties.

Brazil

The U.S. Department of Agriculture estimates that Brazil accounts for approximately 23% of world production. UNICA (Brazilian Sugarcane Industry Association) indicates that approximately 2% of all arable lands available in the country is utilized for sugar cane cultivation. Sugarcane is grown in the northeast states of Ceará, Rio Grande do Norte, Paraiba, Pernambuco, Alagoas and Sergipe, and the south central states of São Paulo, Paraná and Minas Gerais where approximately 90% of all Brazilian sugarcane is grown. Cultivation is primarily on large, mechanized farms.

One of the largest sugarcane growers and sugar producers (raw and ethanol) in Brazil is Cosan (Usina Costa Pinto SA – Acucar e Alcool), which also operates 23 sugar and ethanol mills, including the Costa Pinto Production Plant located in Piracicaba, São Paulo state.

Colombia

Sugarcane is cultivated primarily in the Cauca River Valley (el valle del río Cauca) and the additional provinces of Caldas, Cauca, Risaralda (yields are measured in tons per hectare). The nation’s most important market is the United States.

European Union

Production is declining in the EU, mainly as a result of the implementation of the reform of the sugar support regime.

Guatemala

Guatemala is the largest sugar producer located within Central america. Sugarcane cultivation is located in the south coastal (Pacific Ocean) region of the country, including in the Department of Escuintla. Approximately 75% of annual sugar production is exported to Mexico.

Expogranel, S.A, operates the sugar loading terminal located at Puerto Quetzal on the Pacific Ocean south coast through which most sugar is exported.

India

Maharashtra is India’s largest sugar-growing state, and the states of Punjab, Haryana and Uttar Pradesh also produce sugar. India had a decline in production during the 2008/09 season and is expected to be below target again in the 2009/10 season due to less than average rain fall.

One of the problems that affects sugarcane cultivation / yield in India is that in response to the decline in sugar prices, quite a number of cane growers switched or diversified into other crops. Thus, there is less land committed to sugar cane cultivation compared to in the past.

Another one of the problems that affects sugarcane cultivation / yield in India is that this agricultural sector is dominated by small family-owned farms of small acreage in size thus there is no economy of scale or investment in mechanization.

The domestic price is in Rs per Kg. or Rs per quintal (100 kilograms / approximately 220.4623 pounds).

Bajaj Hindusthan Ltd. (BHL) is the largest sugar (and ethanol) manufacturing company in India.

Japan

In Japan, sugarcane is grown on the Southwestern Islands, at the southern most end of the Japanese Archipelago. Sugar beet is cultivated on Hokkaido Island in the northern area of the Japanese Archipelago.

Mexico

Mexico exports a substantial amount of sugar to the United States: approximately one half of the annual volume of sugar imorted into the U.S. Mexican sugar enters the United States duty free of tariff quota / charges under the NAFTA agreement

Thailand

Sugarcane is grown extensively across the nation of Thailand. There is a price support program in place and there is a two-step negotiation process invloved. At the start of the growing season the farmers and the refiners agree to a primary price (the government acts as the mediator according to the Cane and Sugar Act 1984 and the price is supposed to be not less than 80% of the price anticipated at the end of the growing season). The farmers receive an initial payment from the Bank for Agriculture and Agricultural Cooperatives in order to commence operations for the growing season. As the harvest commences, the farmers and refiners negotiate a final fixed price for the sugarcane. The margin between the primary price and the fixed price is usually paid by the refineries. The two-step negotiated price structure has usually resulted in a condition where the fixed domestic price is above the world price thus the industry is not always competitive.

In Thailand, the area of land measurement is the Rai (1 rai = 0.16 Ha).

U.S. Sugar Production

The United States produces both sugarcane and sugarbeets. More than one-half (approximately 54%) of the sugar produced in the United States comes from sugarbeets. Annually, more than 25 million tons of sugarbeets are produced on over 1.4 million acres, yielding approximately 20 tons of beets per acre and 4 million tons of refined sugar. There are 31 beet sugar processing factories in the U.S., all located in or near producing areas due to the deterioration of sugar content after the beets are harvested.

In the United States, sugarcane is produced in Florida, Louisiana, Hawaii, and Texas with Florida being the largest cane-producing region in the U.S. In Florida, most sugarcane operations a corporate owned while in Lousiiana most sugarcane operations are family owned.

The USDA indicates that Hawaii’s sugarcane production until recently was spread across the islands of Hawaii, Kauai, Maui, and Oahu, but closures of processing plants and competing uses for sugar land have reduced sugar production to two mills on Maui and Kauai. Sugarcane area harvested in Hawaii has decreased from close to 100,000 acres in FY 1981 to an average 21,900 acres in the 2000s. The State’s sugar production has declined from over 1.0 million tons in the first half of the 1980s to 253,000 tons in the 2000s.

In the United States, sugarbeets are grown in five regions encompassing 11 States, and tend to be grown in rotation with other crops. Two of the regions are east of the Mississippi River (Michigan), while the three other areas are in the Upper Great Plains (north central Wyoming, Montana, and western North Dakota) and Central Grain Plains (southeastern Wyoming, Colorado, and Nebraska) and Far West (Imperial Valley of California). Sugarbeet production in the Northwest occurs in Idaho, Washington State, and portions of Oregon. The largest region for sugarbeet production is in or close to the Red River Valley of western Minnesota and eastern North Dakota. Area planted in the Red River region has been growing consistently through the 1990s and has averaged 750,000 acres in the 2000s, or about 54% of total planted U.S. sugarbeet acreage.

On June 12, 2012, the USDA World Agricultural Supply and Demand Estimates (WASDE) indicated: Projected U.S. sugar supply for fiscal year 2012/13 is increased 341,000 short tons, raw value, compared with last month. The increase is due to higher beginning stocks and imports from Mexico. Mexico’s exports of sugar estimated for 2011/12 and projected for 2012/13 are increased due to higher production for both years. Production data for Mexico’s 2011/12 season are nearly complete, while the increase for 2012/13 is based on a favorable growing season since February.

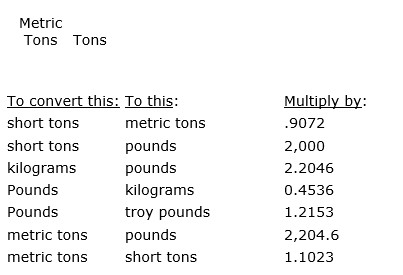

Sugar Crop Calculation / Conversion

- One U.S. ton (avoirdupois) = 2,000 pounds or 907.2 kilograms.

- One metric ton / tonne = 2204.6226 pounds or 1,000 kilograms.

- 1 British ton = 1016 kilograms.

- Lakh (used in India) = 100,000 (one hundred thousand) and is written in India as 1,00,000.

Convert Metric Tons / Tons

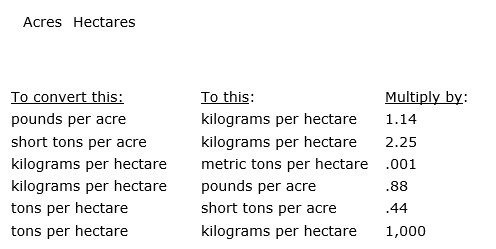

Convert Acres / Hectares

Sugar Consumers

Brazil

A substantial amount of sugar produced in Brazil is sent to ethanol distilleries as the nation relies exclusively on Flex-Fuel vehicles.

India

India is a very large consumer of sugar as it is a key ingredient in Indian culinary tradition. India was a net sugar importer during 2008/09 after a poor crop, and analysts indicate that the country will also be a net importer during 2009/10. Shree Renuka Sugars is India's largest refiner and importer.

United Kingdom

On February 23, 2008, Tate & Lyle, located in the United Kingdom and is the largest sugar cane refiner in the European Union, publicly indicated that it will shift its supply sourcing entirely to the Fairtrade Labeling Program by the end of 2009. This change will only affect the retail market for granulated white sugar sold to U.K. consumers in grocery stores, not bulk industrial sales. The first delivery will be sourced through the Belize Sugar Industries and Belize Sugar Cane Farmers Association.

United States

The American Sugar Alliance indicates that the average U.S. citizen consumes approximately 44 lbs. / 20 kg of sugar per annum, which exceeds domestic production and results in the United States being one of the largest importers of sugar in the world.

The U.S. Department of Agriculture (USDA) indicates that the United States is the largest consumer of sweeteners, including high fructose corn syrup, and is one of the largest global sugar importers (most U.S. sugar imports are raw cane sugar). The United States imports sugar under a system of tariff-rate quotas (TRQ). A TRQ is a two-tiered tariff for which the tariff rate charged depends on the volume of imports. A low-tier (in-quota) tariff is charged on imports within the quota volume. A high-tier (over-quota) tariff is charged on imports in excess of the quota volume. Almost all raw cane sugar, refined sugars and sugar syrups, and sugar-containing products are imported under TRQs for those products. Prior to the start of the fiscal year (October 1-September 30), the Secretary of Agriculture announces the quantity of sugar that may be imported at the preferential in-quota tariff rate during that fiscal year. There is no limit to the quantity that may be imported at the higher over-quota tariff rate.

In addition to the tariff-rate quotas (TRQs), the U.S. sugar program uses price supports and domestic marketing allotments to influence the amount of sugar available to the U.S. market. The program supports U.S. sugar prices above comparable levels in the world market. The origin of the program can be traced to legislation in the Agriculture and Food Act of 1981 (1981 Farm Act). The program has been reauthorized with some modifications in succeeding Farm Acts. An important aspect of the program is that it operates, to the maximum extent possible, at no cost to the Federal Government by avoiding loan forfeitures to USDA’s Commodity Credit Corporation (CCC).

A new measure introduced in the Food, Conservation, and Energy Act of 2008 (2008 Farm Act) to help avoid loan forfeitures is the Feedstock Flexibility Program (FFP). The FFP will divert sugar in excess of domestic food consumption requirements to ethanol production. The main challenge to the program comes from sugar imports from Mexico that now enter duty-free under the terms of the North American Free Trade Agreement (NAFTA).

The 2008 Farm Act provides for USDA to make loans available to processors of domestically grown sugarcane and to domestic processors of sugar beets at set loan rate levels for fiscal years (FY) 2009-13. Loans are taken for a maximum term of 9 months and must be liquidated along with interest charges by the end of the fiscal year in which the loan was made. Unlike most other commodity programs, the sugar program makes loans to processors and not directly to producers. This is because sugarcane and sugar beets, being bulky and very perishable, must be processed into sugar before they can be traded and stored. To qualify for loans, processors must agree to provide payments to producers that are proportional to the value of the loan received by the processor for sugar beets and sugarcane delivered by producers. USDA has the authority to establish minimum producer payment amounts.

The loans are nonrecourse. When a loan matures, USDA must accept sugar pledged as collateral as payment in full in lieu of cash repayment of the loan, at the discretion of the processor. “In-process” sugar and syrups must be converted into raw cane or refined beet sugar at no cost to the CCC before being eligible for forfeiture. The processor is not required to notify USDA of the intention to forfeit the sugar under loan. The loan rates for raw cane and beet sugar are set in the 2008 Farm Act.

The loan rate for raw cane sugar is:

- 18 cents per pound in FY 2009,

- 18.25 cents per pound in FY 2010,

- 18.50 cents per pound in FY 2011, and

- 18.75 cents per pound in FY 2012-13.

The loan rate for refined beet sugar is:

- 22.9 cents per pound in FY 2009 and

- 128.5% of the loan rate for raw cane sugar in FY 2010-13.

The 2008 Farm Act allows processors to obtain loans for in-process sugar and syrups at 80 percent of the loan rate.

Molasses

After the sugar is crystallized in the C-products (low raw) vacuum pans, the crystal/syrup is discharged into cooling crystallizers and retained for approximately 32 hours to optimize the crystallization. The product is then separated in the low raw centrifugal, with the C-sugar returning to the melter to become a component of the standard liquor. The syrup left after this process is known as molasses. Although molasses is approximately 50 percent sugar, the concentration of non-sugars is so high that no further crystallization is economically possible in a standard processing facility. The molasses is stored in large tanks to be shipped to other companies which use it in the production of products such as pharmaceuticals and alcohol.

Molasses is a thick solution which contains approximately 50% sucrose. It contains introgenous compounds such as betaine, invert sugar, organic acids such as glutamic acid, and other components that come from the sugar beet.

Because of its high content of sugar and certain nitrogenous constituents, molasses is a valuable raw material used by the fermentation industry. It is also used in animal feed supplements, and by the pharmaceutical industry. It is also used in animal feed supplements, and by the pharmaceutical industry. Molasses is available in 55 gallon drums or in bulk.

Beet molasses is a heavy, dark brown liquid which is approximately 50 percent sugar. At this percentage, it is not feasible to remove additional sugar in a conventional processing facility. However, this sugar content makes beet molasses appealing for use in the fermentation industry. It is especially useful in the production of bakers’s yeast, citric acid, pharmaceuticals, and alcohol. As an animal feed supplement, molasses adds nutrient value, texture, and palatability to livestock as well as reducing dust.

Sugar Futures Market & Pricing

Overall, sugar prices reached a peak in May 2006 and then declined up to the end of 2007. Prices have increased steadily since 2008 after a production / stocks deficit for 2008/09.

The Futures Contract on Sugar No. 11 (raw sugar) is traded on NYMEX. The contract price is in US dollars and cents. There is no futures market for U.S. refined sugar.

The Futures Contract on Sugar No. 16 (raw sugar) is traded on ICE. The contract price is in US dollars and cents per 112,000 lbs. (50 Long Tons).

Futures Contract on Sugar No. 407 (white beet, cane crystal sugar or refined sugar) is traded on NYSE Euronext LIFFE. The contract price is in US dollars and cents per tonne (metric ton). The is the former LIFFE No. 5 contract.

Futures Contract on Sugar (cane crystal sugar) is traded on Bolsa de Mercadorias & Futuros (Brazil). The contract price is in US dollars and cents per 270 bags of 50 net kilograms each.

The majority of world sugar is either consumed in the country where it is produced under government-controlled pricing arrangements or exported from one country to another under pre-arranged agreements. The sugar which is not subject to such agreements is freely traded among a number of nations, corporations and individuals. The free market for sugar is thus classified as a “residual market” – a market in which sugar traded freely is only a residual of total world production. Since the free market for sugar is typically 20-25% of world production, a 5% change in production can represent a 25-33% change in free market sugar supply; one of the reasons for the high historical volatility of sugar prices.

In addition to imbalances between production and demand, a number of other factors affect sugar demand, including refinery activity, consumer income, candy and confectionery sales, and its use in new technologies, such as the production of ethanol as an automobile fuel. The futures market is also strongly influenced by existing, approaching and forecasted weather conditions.

Sugar is prized for its sweet taste and has many other functions in cooking and baking. It contributes texture and color to baked goods. It is needed for the fermentation by yeast, which causes bread to rise. Sugar acts as a bulking agent (ice cream, baked goods) and preservative (jams, fruits), and it imparts a satisfying body or "mouth-feel" to beverages. In non-sweet foods, such as salad dressings, sauces and condiments, sugar enhances flavor and balances acid content in tomato and vinegar-based products.

Sugarcane cultivation and rum distillation are still important products to the Caribbean Basin nations. Sugarcane is still cultivated in Belize, Barbados, Cuba, Haiti, the Dominican Republic, Guadeloupe, Guatemala, Guyana, Jamaica, Grenada and St. Kitts. The regional distilleries (with the exception of St. Vincent & the Grenadines and Dominica) are represented by the West Indies Rum and Spirits Producers Association (WIRSPA, based in Barbados). In 2004, the rum industry within the Caribbean region was assisted by a €70 million investment from the Integrated Development Programme for the Caribbean Rum Sector for facility renovation and modernization and for marketing.